SmartLab

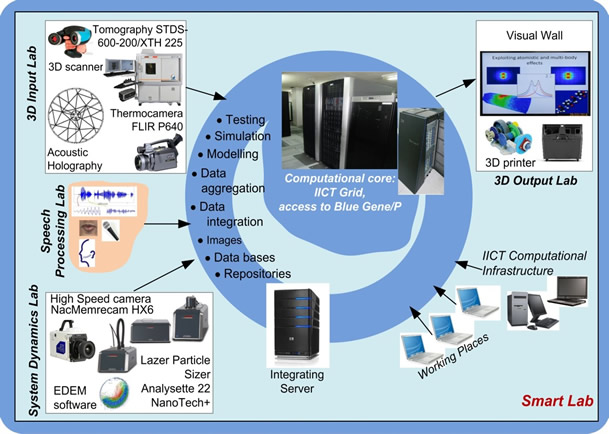

The Institute of Information and Communication Technologies - BAS has unique equipment for research, modeling, optimization and intelligent management - SmartLab laboratory (fig.1), included in the National Road Map for Scientifical Infrastructure (Chapters “ICT” and “Mechatronics and clean Technologies”). It was purchased under the AComIn project of the European Commission's 7th FP to expand the possibilities of using the high-performance computing equipment available at the Institute for solving a number of application problems, expanding the Institute's participation in technology transfer to industrial enterprises, national and international projects, and high quality training for masters and PhD students. The AComIn project also attracted young scientists, including postgraduate post-doctoral students, to enhance the scientific capacity of ICT. The SmartLab Lab Manager is Prof. Dr. Dimitar Karastoyanov

Fig. 1. SmartLab Equipment.

SmartLab equipment:

High-Speed Camera NAC MEMRECAM HX6

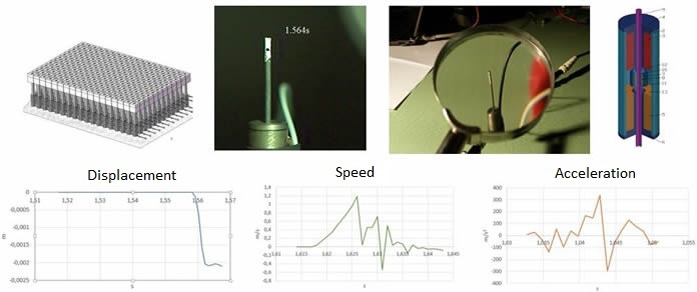

The high-speed camera (fig. 2) can record from 2000 to 370 000 fps. Resolution, depending from fps:

Build in fast memory 32 GB, 3 different lens (incl. vario), temperature calibration, additional light projectors with 1 KW, control software and software with possibilities for measuring position, speed, acceleration, working which can work with different programs, camera remote, USB, Ethernet interfaces.

Fig. 2. High-Speed Camera.

Applications: car safety tests: impact, Airbag, suspension, tires, braking system, transmission. Another important application is ballistic tests, tracking projectiles, explosives, pyrotechnics, missile launcher. Also is widely used in the production and automation of machine design, high-speed production lines monitoring, packaging, briquetting of scrap, research, etc.

Fig. 3. Applications.

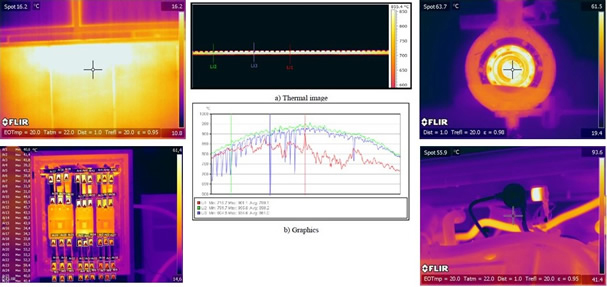

Infrared Thermal Camera FLIR P640

The infrared wave length is used from the thermal cameras, so they can "see" and measure thermal energy, emitted from an object. That energy is known to the people as temperature. The infrared camera (fig. 4) is contactless device, which locates infrared energy and converts it to electronic signal, used to create thermal image on the screen, and obtain temperature equations. The "felt" heat can be measured or determinated very precisely, which allows not only surveillance, but also and diagnostics. The infrared cameras, which contains measurement tools allows to the specialists to predict problems in electricity, mechanical objects, etc. The temperature measurements can be compared to the normal working temperature of the objects, and a significant change in the temperature means problem with reliability of the component.

Specifications:

Fig. 4. Infrared camera.

Applications: cars, tires, braking system, transmission, automation, machine survey, monitoring of buildings, equipment, electrical installations, mechanical loads, research, etc.(fig.5).

Fig. 5. Applications.

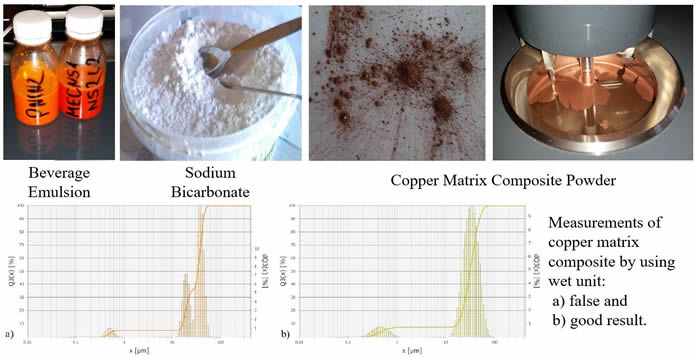

Laser nano particle sizer FRITSCH Analysette 22 NanoTec plus

Measures the size and distribution of particles in nano and micro range. It can be used for bulk materials, powders, suspensions and liquids, organic compounds, etc. Analyzer ANALYSETTE 22 NanoTech + - Fig. 6, consists of measuring module, "wet" dispersion unit, measuring from 0.01 to 2000 microns, "dry" dispersion unit measuring from 0.1 to 2000 microns.

Fig. 6. Laser nano particle sizer.

Applications: automotive, pharmaceutics, cosmetics, food, mining, powder metallurgy, etc (Figure 7).

Fig. 7. Applications.

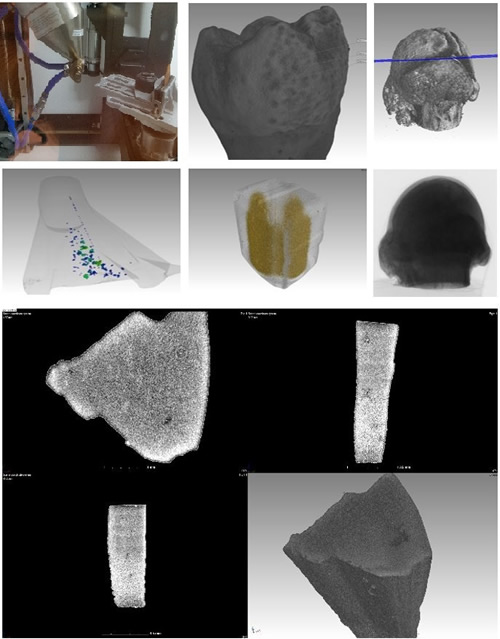

3D Computed Tomography Nikon XT-H 225

Computed Tomography Nikon XT H 225 (fig. 8) for investigation of a wide range sample materials and sizes with a power range of 20 to 225 KV. Ideal for both laboratories and production as well as for scientific purposes. Enables real-time X-Ray 2D visualization. It has a five-axis positioning system. The load capacity of the rotating table is 15kg and the maximum sample dimensions are 15x15x15cm. The maximum detector resolution is 1900x1500 with an active area of 467 cm2, x-ray spot 3 μm. The system also has computer software for analysis and 3D reconstruction of the internal structure of the scanned object.

Fig. 8. 3D Computed Tomography.

Applications: vehicles (connectors, injectors, sensors, tubes and); to find micro cracks in the materials; to study the internal structure of natural and biological materials, to detect and analyze defects, inspecting complex mechanisms, measuring the dimensions of internal components, comparing parts to CAD details, expanded material research, digital archiving of model (Figure 9).

Fig. 9. Applications.

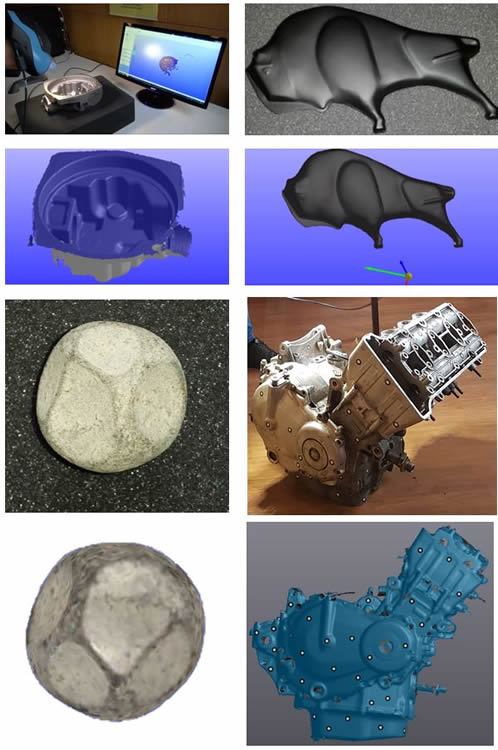

3D mobile color scanner Creaform HandyScan VIUScan

The mobile scanner (fig. 10) allows precise 3D surface scan of objects, 18,000 measurements per second, geometric resolution (0.040-0.050 mm), accuracy up to 50 μm, color 24 bit, text resolution 250DPI, output formats: .ma, .dae, .obj, .x3dz, .x3d, .zpr, .wrl, .fbx, .ply, .stl, .txt. Self-positioning system. It does not need external tracking or positioning devices. It uses triangulation to determine the relative position in real time. The scanner can be calibrated at any time, and after calibration ensures optimum performance. Allows real-time visualization of the scanned object.

Fig. 10. 3D mobile scanner.

Applications: scanning and building 3D models of objects with the possibility of subsequent software modeling and / or 3D printing, overlaying of objects, reengineering, design, production, quality control, preservation of cultural and historical heritage, etc. (Figure 11).

Fig. 11. Applications.

3D color printer 3D Systems ProJet 460 plus

The full color 3D printer ProJet 460Plus (fig. 12) allows to create beautiful, photorealistic details in CMY color with the ability to use full texture. This allows for better visualization of design. The ColorJet Print technology allows the fastest print speed, 5x-10x faster than any other technology, to develop models in hours rather than days. Based on reliable and affordable CJP technology, the ProJet 460Plus prints details up to 7 times less cost than other technologies.

Specifications:

Characteristics of the produced parts, depending on the infiltrant:

Fig. 12. 3D printer.

Applications: modeling of concepts, models for marketing and sales, architecture and construction, cars, art, education, etc. (Figure 13).

Fig. 13. Applications.

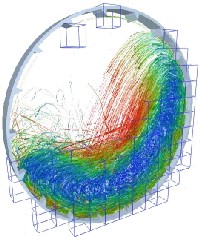

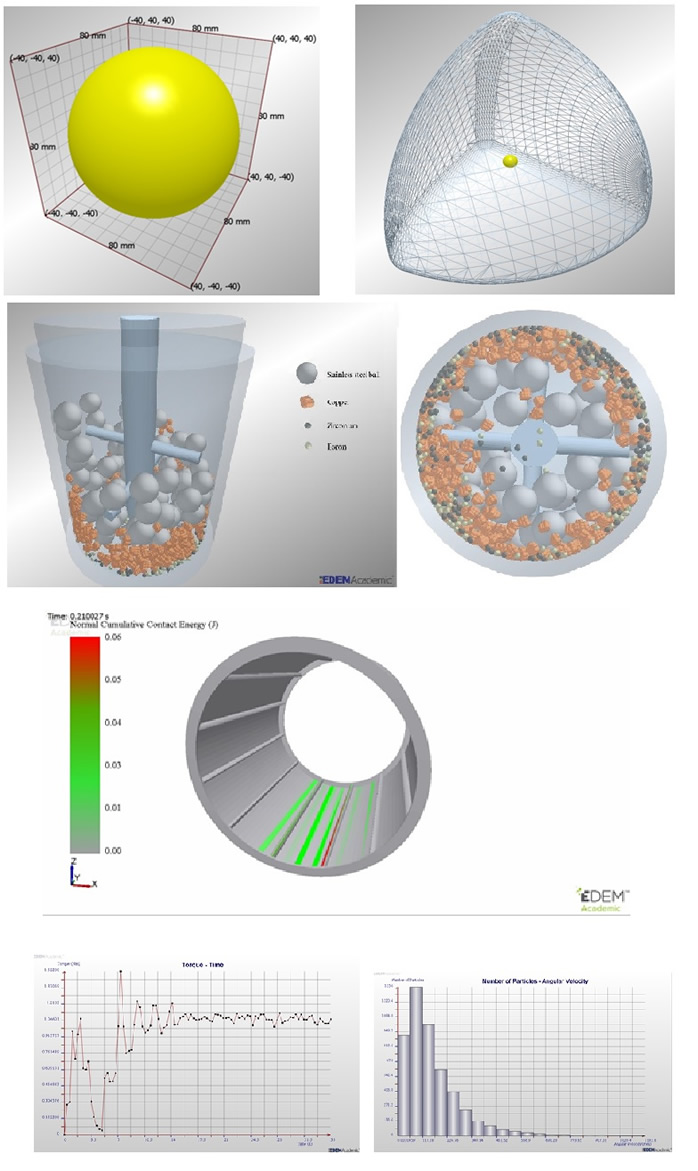

3D Software package for computer simulations EDEM (Discrete Element Method)

The program package (Fig. 14) includes an interface to EDEM API, importation of CAD models, EDEM-CDF module, Data Module, Heat Transfer Module. Compatibility with other Finite Element softwares. It consists of three main parts: EDEM Creator, EDEM Simulator, EDEM Analyst

With EDEM Creator, bulk material models can be easily and quickly created. Instruments are designed to easily model the shape, density and contact of the particles, the software offers the possibility of importing particle templates from other CAD products.

EDEM Simulator is where the software parameters must be set and controlled, which is highly paralleled and works very well with multi-core machines. Parallel efficiency increases speed when working with large models.

EDEM Analyst provides tools for post-processing, analysis, visualization, and downloading of simulation data, EDEM provides a fast 3D visualization of the particle behavior and allows to be saved as a photo or video.

Fig. 14. 3D Software.

Applications: industry, modelling and analysis of loading and unloading efficiency , defines wear areas, harvesting machinery (transport and grain separation), prevention of blocking and spillage of conveyor belts, identification of excessive material speeds and dispersed flow, distribution optimization and spreading of materials, processing of bulk and mining materials, mixing efficiency, etc. (Figure 15).

Fig. 15. Applications.