Project Title:

3D Digitalization of Objects from National Cultural-Historical Heritage.

Funding: National Science Fund, Competition for financial support for research projects – 2017.

Duration: 36 months

Start Date: December 2017

Beneficiary: IICT-BAS,

Project Coordinator from IICT-BAS: Prof. Dr. Dimitar Karastoyanov

Abstract: in recent years, museums have welcomed millions of visitors to their galleries and exhibitions. However, museums have made little progress towards a concrete understanding of what visitors actually see when they look at works of art. While the impact on some visitors is very strong, the average visitor stops at less than half the exhibits and spends less than 30 seconds on individual artifacts ‒ in most cases, much less.

Another important aspect is by using the possibilities of the information and communication technologies to provide access to the cultural and historical heritage objects for people with disadvantages (for example visually impaired or blind people) so that they can also "see" by touching with their fingers and hands. This will provide them better understanding of the relevant presented object – painting, flag, etc.

Also, the results of the proposed project will give the opportunity to a wide range of users to meet the art in a closer way - with 3D models of unique and valuable cultural and historical artifacts that are now kept in vaults for security reasons and these treasures are inaccessible.

Until now, there has been almost no experience in 3D digitization of cultural and historical heritage, especially for disadvantaged people (visually impaired). In the world the ICT's main achievements in this area are mostly implemented in an assistive graphical user interface for people with visual impairments, so they can use computers (Windows icons, etc.).

Objects of the project are to build 3D models of scenes from the national cultural and historical heritage by extracting images from 2D sources - pictures, paintings, engravings. In the presented task, at the first place must be modeled a 3D representation of the historical battles of the “Shipka Epopee” - August 1877, in connection with the upcoming celebrations in 2017 and 2018, as well as the presentation of results on the date of the National Day March 3, 2018, Related to possible foreign high-level delegations for the celebration, the Bulgarian EU Presidency in 2018 and others.

Separately, the battle for the Samara flag near Stara Zagora and the feat of Lieutenant Colonel Kalitin will be presented, as well as by 3D scanning with an available 3D scanner of nowadays presentations of the relic near Stara Zagora. For visually impaired people, 3D representation of different photos, paintings and scenes with additional alphabet of Braille inside the contours of the figures. Thus, people with visual impairment by touch will be able to "present" the picture, "see" it and "read it".

Rewarded for The "Best Innovative Project for 2020" in a Competition organized by the Innovation and Technology Development Council with the Bulgarian Chamber of Commerce and Industry.

Project Title:

Hybrid electromagnetic systems with magnetic modulation.

Funding: National Science Fund, Competition for financial support for research projects – 2017.

Duration: 36 months

Starting date: December 2017

Beneficiary Organization: TU-Sofia

Project Coordinator: Prof. Dr. Ivan Yatchev

Partner Organization: IICT-BAS,

Project Coordinator from IICT: Prof. Dr. Dimitar Karastoyanov

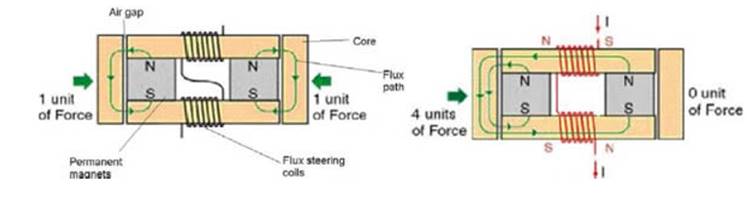

Abstract: The applications of modern generations of magnetic and magneto-solid materials in recent years are expanding rapidly and lead to increasing the energy efficiency of a wide range of static and dynamic electromagnetic systems.

The development guidelines for their applications are grouped in two directions: - use of mechanical forces and moments;

- a transformation of electrical energy by modulation of magnetic fluxes.

Both groups of applications are evolving towards the use of higher frequencies of action, which results to higher energy performance. These applications require a good understanding of both the static and the dynamic characteristics of the systems, and of the used permanent magnets. Existing knowledge about the characteristics of permanent magnets encompasses very well their static characteristics. There is a lack of knowledge about the dynamic characteristics of especially the latest high-energy permanent magnets.

The main objective of the project is to acquire new knowledge about the characteristics of modern models of permanent high-energy magnetic magnets and the new generations of magnetic materials and in particular their dynamic characteristics, incl. and their resonance properties in the composition of electromagnetic systems in various methods for modulation of magnetic fluxes.

In addition to the theoretical research, the project will also aim at the implementation of modern experimental studies of the systems subject to the project. Modern methods for computer modeling and optimization as well as for computer-controlled experimental research will be used for the implementation of the project.

Project Title:

Design and modelling of metal matrix composites.

Starting date: 01.11.2018

Duration: 18 months

Project type: H2020-MSCA-IF-2017

Grant Agreement No: 797372

Fellow: Dr. Jovana Ruzic

Supervisor: Prof. Dr. Dimitar Karastoyanov

Beneficiary Organization: IICT-BAS

Abstract: Excellent mechanical properties make metal matrix composites (MMCs) an attractive and desirable material in many industries. However, manufacturing costs of MMCs are currently very high mainly due to lack of material design database and limited knowledge related to their behavior in various working conditions. This proposed research aims to improve understanding of the relation between MMCs production parameters and their properties. The proposed research plan has two main assignments: firstly, to experimentally obtain optimal processing parameters for producing highly conductive, strengthened copper matrix composites with uniform dispersion of submicron and nano-sized reinforcements; secondly, to create a computational model for mechanical alloying process and for predicting the behaviour of MMCs. Powder metallurgy will be used for MMCs production. It is expected that with increasing mechanical alloying time the distribution of reinforcements (in-situ formed during densification process) in metal matrix become more uniform which is a requirement for excellent mechanical properties. Investigating the influence of size and volume fraction of in-situ formed reinforcing nanoparticles on its microstructural, mechanical and physical properties will be the overall objective of the experimental work. Proposed techniques, data collection, and analysis will identify the relationship between process parameters and material behaviour, which will contribute to the establishment of process parameters for fabrication of MMCs. Obtained results will present a good database which can accelerate further research, development and possible implementation of MMCs. Moreover, creating computational models for control of microstructure and process design of MMCs will contribute to a better understanding and predicting the behaviour of a wide variety of MMCs. It will provide a cost effective solution in the manufacturing of MMCs which will expand possibilities in the design of new products.

For more information please visit the web page of the DeMoMet project. The DeMoMet project has received the funding from the European Union’s Horizon 2020 research and innovation programme under the Marie Sklodowska-Curie grant agreement No 797372.

Keywords: metal matrix composites, integrated computational materials engineering, powder metallurgy, microstructural characterization, mechanical alloying, mechanical properties.

Project Title:

Centre of competence MIRACle - Mechatronics, Innovation, Robotics, Automation, Clean technologies

Funding: Operational Program Science and Education for Smart Growth

Duration: 60 months

Starting date: 2019

Beneficiary Organization: Institute of Mechanics at the Bulgarian Academy of Sciences

Project Coordinator: Prof. PhD Petar Djondjorov

Partner Organization: IICT-BAS,

Project Coordinator from IICT: Prof. Dr. Dimitar Karastoyanov

Abstract: The MIRACle project aims to establish and sustainably operate a Center of Competence in the thematic area “Mechatronics and clean technologies”. It employs leading scientists, successful researchers and talented inventors in all scientific and applied fields in this field.

The center has a modern research infrastructure and its own research and innovation programs. MIRACle provides an opportunity for the competitive development of the scientific field “Mechatronics” and full scientific service of the economic sectors related to Mechatronics and Clean technology field.

Specific objectives:

- Development of researchers in the field of “Mechatronics”, including by attracting leading scientists and researchers (from the country and abroad) to conduct research. The project provides an opportunity for the specialization of researchers and innovators at a high level;

- Creation and introduction of new teaching and educational methods and programs in the field of mechatronics and clean technologies, both for researchers and business representatives;

- Establishment of strategic partnerships with leading technological research centers, organizations, and companies in Bulgaria and Europe to initiate common projects;

- Creation of start-up companies.

The Center’s infrastructure is an organized network of resources located in four main bases, which include the creation of new and/or modernization of existing research laboratories, in the following areas:

* Innovative solutions in robotics and automation;

* Biomechatronic systems;

* Intelligent environments, processes, and technologies in mechatronics;

* New methods and means for control and testing of mechatronic elements;

* Mathematical provision and modeling of complex systems and processes;

* 3D modeling, development and introduction of pilot models of elements, details, and systems for mechatronics.

Project Title:

Intelligent Animal Husbandry

Funding: National Science Program of the Bulgarian Ministry of Education and Science

Duration: 36 months

Starting date: March 2021

Beneficiary Organization: Thracian University - Stara Zagora

Rector: Assoc. Prof. Dobri Yarkov, Ph.D.

Project Coordinator: Assoc. Prof. Darina Zaimova, Ph.D.

Partner Organization: IICT-BAS,

Project Coordinator from IICT: Prof. Dr. Dimitar Karastoyanov

Abstract: The main goal of the research program is to conduct fundamental and applied research. The results will be provided to the livestock sector with innovative methods and tools for the intelligent and efficient animal husbandry with reduced resources and reduced environmental impact.

The main activities and tasks are logically planned in 12 Work Packages:

Work Package 1: Robotic milking systems - Creation of systems for automatic milking of cows and application of robots in various livestock processes.

Work package 2: Robotic systems and forms for animal husbandry - Automatic feeding, watering, cleaning, and disinfection of premises, automatic weighing and counting of animals, etc.

Work Package 3: Intelligent Systems for Genetic Progress - Genomic Assessment Systems. Semen sexing systems. Creation of technology for the production of sexed embryos.

Work package 4: Intelligent systems for monitoring and analyzing the productivity of pastures and meadows - stationary and mobile sensor complexes for sampling and monitoring of soil and grassland parameters, computer vision and remote methods for obtaining information about the condition and qualities of plant mass.

Work Package 5: Cyber-physical monitoring systems - including IoT devices and sensor systems for monitoring the environment, health, growth, behavior, reproduction, emotions and stress of animals, as well as GPS marking for tracking and counting animals.

Work Package 6: Cyber-physical systems for intelligent management of animal husbandry complexes - including IoT devices and sensor systems to control humidity, temperature, ventilation, lighting, dust, carbon dioxide levels and other parameters.

Work package 7: Unmanned aerial vehicles - equipped with outdoor animal tracking and counting cameras and infrared animal health (temperature monitoring) cameras.

Work Package 8: Service robots and drones for storage and/or delivery of finished products - to manage customer interaction for order collection and delivery, which will optimize the process, increase capacity and reduce delivery time.

Work package 9: Stock management - food and liquids for animals, cold stores for meat and milk. Processing and distribution of supplies.

Work package 10: ICT technologies in financial, economic and reporting activities - risk assessment, databases, communications, internal network, Internet.

Work package 11: Digital technologies in teaching, learning, working with young talents and special target groups.

Work Package 12: Intelligent Waste Management as an Element of the Circular Economy - Including the Disposal of Biodegradable Waste, Reducing Environmental Pollution and Improving Energy Efficiency in Livestock Farms.

Project Title:

Innovative service "United Office"

Funding: Operational Program Innovation and Competitiveness

Duration: 36 months

Starting date: 2018

Beneficiary Organization: Vivacom

Partner Organization: IICT-BAS,

Project Coordinator from IICT: Prof. Dr. Dimitar Karastoyanov

Abstract: The product (service) innovation proposed for development with this project is precisely in the field described in this way and has the working title "United Office", based on the "System architecture of the process for providing complex services". In essence, this is a telecommunications service that will be developed to provide industry-leading reliability, security, call efficiency, allowing communication regardless of the end device and infrastructure (SIP phone, tablet, tablet, computer, mobile phone, etc.). At the same time, the United Office will provide mobility through diverse, unique combinations of sub-services such as face and voice recognition, which will provide access and rights in conference and video meetings, presenting one number and managing calls or defining several different numbers. When using the service after its development, the user (especially to business customers, large enterprises) is expected to be able to manage their calls, as well as receive calls from an end device, which he decides by checking access to the secure network. This will ensure the confidentiality of all his data - files, messages, records of conference calls, and confidential information. Once registered and granted access, he will have the unique opportunity to receive a call on his landline or mobile phone, on his computer or vice versa. At the same time, the service will have unique functionality for automatic speech recognition and speech-to-text conversion - this will allow a completely new way of working in the field of conducting and recording video meetings and conference calls. The automatic recognition and conversion of voice and its conversion into text makes it possible to receive an e-mail corresponding to the language in which the meeting was held. Additionally, the service will be developed with built-in functionalities for electronic signing of the automatically generated document through a qualified electronic signature, through a cloud-based platform for electronic signing and verification of documents and messages. In essence, the United Office will be a cloud service that will be developed to provide a new type of private exchange, providing both fixed and mobile phone calls, without the need for complex end-user infrastructure. The large office will be able to share large data, such as files, video conferencing, work screen sharing and integration with various applications and SIP clients, with unique authorization and identification capabilities through face and voice recognition and speech to text conversion, electronic signing in a cloud environment. Organizations will be able to communicate with each other via messages, manage their status and transfer calls from one device to another. The user will be able to set their melodies, define areas of working time in which to ring one line, and then transfer to the other.

Project Title:

Innovative photovoltaic tiles for energy efficient buildings

Funding: National Innovation Fund

Duration: 36 months

Starting date: 2020

Beneficiary Organization: DSI

Partner Organization: IICT-BAS,

Project Coordinator from IICT: Prof. Dr. Dimitar Karastoyanov

Abstract: the main goal of the project is related to the development of innovative energy-efficient photovoltaic roofing systems and integrated smart energy modules for the transformation of existing buildings into "smart buildings", and as a result new productions by DSI Ltd. in the following areas:

• Integration of solar tiles in roof structures;

• Design and evaluation of roof structures and systems;

• Implementation of software applications for energy consumption;

• Implementation of software applications for monitoring consumption and energy storage;

• Implementation of software applications for optimization and smart distribution of energy consumption and storage;

• Inclusion of the system in the “smart building” panel;

• Inclusion of the system in the panel "innovative office";

• Implementation of smart grids "Smart Grids".

The specific objectives are related to:

• Creation of new jobs and increase of the employment of the qualified specialists in the field;

• Improvement and development of the positions of the company, which will have the opportunity to develop its potential and stabilize its positions;

• Energy efficiency, new materials, protection of the environment and human health;

• Increasing the volumes of market realization of the company's products.

Project Title:

Research and optimization of the interaction between grinding bodies and media with an innovative shape

Funding: National Science Fund, Competition for financial support for basic research projects – 2020

Duration: 36 months

Start Date: November 2020

Beneficiary: IICT-BAS

Project Coordinator: Assoc. Prof. Nikolay Stoimenov, Ph.D.

Abstract: The extraction of ores with sufficient content of minerals is processed and the output material is the so-called starting product. The implementation of an effective enrichment process requires the starting product to undergo technological processing to average the mineral and chemical composition of the product. Processing is carried out in mills (ball, autogenous, semi-autogenous).

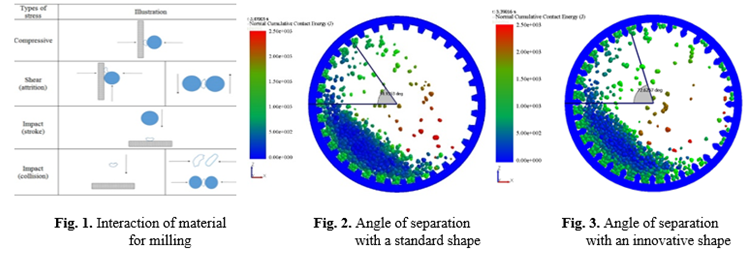

The Grinding of different materials is an important industrial process in which the material is crushed and milled to a certain pre-desired size by the interaction between material, grinding bodies, and grinding media (Fig. 1).

The main factors influencing the grinding of material are grinding bodies and grinding media.

In modern operating conditions, in addition to technological, structural, and economic requirements, attention is also paid to ecology, energy efficiency, operational reliability, as well as the human factor. Key factors: loading with a certain percentage of grinding material; percentage to be filled; the size of the grinding bodies used (if possible to be of the smallest dimensions, thus achieving a maximum contact area between the media and the grinding material); grinding time; it is not allowed to increase the temperature of the mill, etc.

Crushing and grinding are carried out with the help of grinding bodies and grinding media (lifters/liners), which are subjected to an aggressive working environment, in addition to the grinding bodies themselves. The grinding process is extremely energy-intensive (worldwide about 20% of the energy is used for this process). For this reason, it has been heavily researched. Of great importance is the proper functioning of the mill, grinding bodies, lifters, speed, separation angle (Fig. 2. Standard lifter form, Fig. 3. Innovative lifter form), angle of incidence and other factors to achieve good performance and high productivity. Increasing the separation angle at the same set speed (consumed energy) will increase productivity, reduce the required electricity and reduce the time to grind the output. This will help the energy efficiency of the process.

The main goal is research, optimization, modeling, simulation, laboratory research, and verification of the results of grinding bodies and grinding media. The listed goals seek the acquisition of new knowledge, achieving better results of the process grinding such as energy efficiency, durability and ecology.

Project Title:

Digitalization and Creation of 3D objects and tactile tiles for visually impaired people,

Partners: Sofia City Art Gallery, Sofia municipality

Duration: 7 months

Start Date: 2019-2020

Organization: Sofia Art Gallery

Partner Organization: IICT-BAS,

Project Coordinator from IICT-BAS: Assoc. Prof. Nikolay Stoimenov, Ph.D.

Abstract: The project aims to be digitalized paintings from Sofia city. The paintings are part of an exhibition, dedicated to Sofia and 140 years since the city was declared the capital, named “Words, images and places" The digitalized paintings are transformed into 3D tactile tiles paintings. The 3D printed tactile tiles are used for making an exhibition about the city of Sofia accessible to people with visual impairments.

The used technique until now for the making of tactile tiles is based on the following steps: digitalization of the painting, segmentation of the details in the painting. The next step is the separation of the painting content, shown in fig. 1 to extruded solid figures and objects (1), and by using contours of the objects (2) are selected the next objects on the painting. It follows solid objects, contours, solid objects, contours, etc. The final steps are creating a 3D model, and 3D printing the modeled tactile tile, which brings more information to the visually impaired or blind. Additionally, for easier orientation of users, the details in the image shown in fig. 1 include an annotation of Braille letters and symbols (3). A Legend (4) is placed on the bottom of the image and consists of the content from the Braille letters and symbols. Also is given information about the painting, written in Braille the name of the author and work (for paintings, tapestries, portraits, etc.).

The used method for complex painting with more details is patented [D. Karastoyanov, N. Stoimenov, S. Gyoshev, Tactile graphical tile for visual impaired., BG Patent No №67212/17.12.2020]. Another patent application for making tactile tiles for representation of portraits is registered [Stoimenov N., Karastoyanov D., Gyoshev S., Tactile graphic portrait for the visual impaired, Patent Application, Reg. No 113199, priority from 31.07.2020].

Project Title:

Creation of a flexible methodology for development

and management of innovative projects in scientific organizations

Funding: National Science Fund, Competition for financial support for basic research

projects on societal challenges – 2018

Duration: 36 months

Start Date: December 2018

Beneficiary: UNWE

Project Coordinator from IICT-BAS: Assoc. Prof. Nikolay Stoimenov, Ph.D.

Abstract: The project aims at creating a flexible methodology for development and management of innovative projects in scientific organizations (FMIPSO), based on the flexible methodologies: Lean startup, Agile, Scrum, Design thinking, User centricity and User innovation. The creation of FMIPSO addresses the weak success of the developed and realized innovations by Bulgarian scientific organizations. This problem directly influences the last position of Bulgaria in a numerous of indices and ratings, assessing innovation performance, innovation progress and performance (European Innovation Scoreboard, Bulgarian National Statistical Institute, Innovation.bg, Eurostat, World Bank, Global Innovation Scoreboard , The World Economic Forum, the Global Competitiveness Report, Innovation and the Organization for Economic Mutual Assistance and Development - OECD). This lack of good innovation performance by scientific organizations further increases the distance and integrity of the science-business-related innovation industry.

For the purpose of the testing and creating the final version of the flexible methodology, divergent scientific innovative sub-projects have been selected as a principle of the choice were: high multidisciplinary; scientists interested in developing innovation; specific research projects to develop innovations that are shaped as work packages in the current project to overcome a societal challenge such as increasing competitiveness and productivity of the economy in line with the ISIS areas. The sub-projects that will be carried out within the project will not only be used for comprehensive and in-depth approbation of the developed FMIPSO but they also meet the societal challenges of the competition recommendations and the priorities of ISIS. These are:

• "Innovative method for 3D presentation of plane culturally-historical sites by tactile plates for the disadvantaged users (low sighted or visually impaired people)" - Technical sciences, Institute of Information and Communication Technologies at BAS;

• "Detection of mutations in the EGFR gene in invasive urinary bladder tumors" - Medical Sciences, Medical University-Sofia, Medical Faculty, Department of Medical Genetics;

• "Diagnostics, condition assessment and analysis of reinforced concrete elements" - Technical Sciences, Institute of Information and Communication Technologies at BAS with the participation of scientists from the University of Structural Engineering & Architecture

(VSU) "Lyuben Karavelov" – Sofia;

Part of the young scientists know each other of their visit in Joint Research Center (JRC) in Ispra, Italy, which took place in the period 27-29 June 2018. The selection for the visit of young scientists was made by the Ministry of Education and Science, requiring them to be finalists in the competitions of the National Scientific Fund, Bulgarian Academy of Science, and Club Young Talents. After realizing one of the main concepts of the JRC for interdisciplinary research and innovation in each of the various fields, some of us have decided to realize this idea with this project.

As a result of the scientific project, the team pursues the overall goal of increasing innovation from scientific organizations significantly. For dimensions of this innovation growth, the team has the following dimensions: number of innovations; level of novelty of innovation; level of consumer interest in the innovations developed by research organizations; adaptability of innovations developed for technological innovation; adaptability of innovations developed for transfer to other sectors and directions; management skills and processes in the innovation process; direct and accessible relationship scientific organization-business organizations; a level of quality improvement of the current state of the problem that innovation permits; diversifying and opening up the process of innovation in the direction of - open innovation and innovation development network.

Project Title:

Investigation and optimization of milling processes by using innovative grinding environments (lifters)

Funding: Competition for financial support for project of junior researchers and postdocs – 2017.

Duration: 18 months

Starting date: 20 December 2017

Beneficiary Organization: IICT-BAS,

Project Coordinator: Assist. Prof. Dr. Nikolay Stoimenov

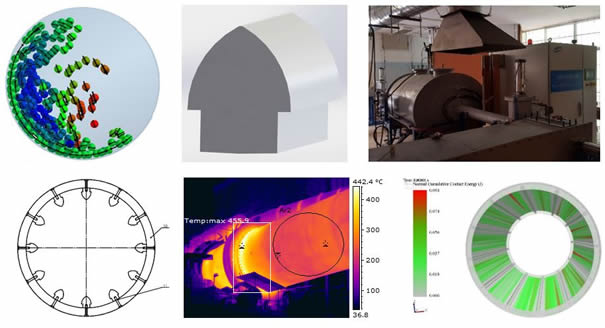

Abstract: Milling of different materials is an important industrial process in which the material is crushed and milled to a desired predetermined size. Ball mills are widely used in various production areas, mainly metallurgy, mining and mineral processing, cement production, chemical industry, pharmaceuticals and cosmetics, ceramics, laboratory research, and etc. Depending on the specific area of application, the treated materials are with different properties like hardness, size, chemical composition and structure, examples of various types: ores, minerals, limestones and others. The project proposes a new technology to create a high hardness grinding environment with innovative high-temperature technology by using a Taman furnace. The sintering and use of nano elements of high wear-resistant Bor-based materials is an innovative novelty. A vacuum furnace will be used to cure the parts. To test the composition of the incoming materials (powders) as well as particle size distribution in the range of 10 nanometers - 2000 microns, Laser Nano Sizer Analyzer 22 NanoTech + will be used. 3D Computer Tomography NIKON XT H 225 will be used to study the 3D internal structure of materials and alloys with 3 microns accuracy. The two appliances, as well as Tamann and Vacuum furnaces, are available. Samples will be produced to study their characteristics. Experimental tests for hardness and wear resistance will be implemented. The working regime of the mill process will be modeled and simulated in real-size mills by using the EDEM Software's discrete-element software, also available at IICT-BAS. The aim of the project proposal is to be investigated the milling processes and optimize them by innovative grinding media (lifters).

Project Title:

Research and optimization of milling processes with innovative forms of grinding bodies and environments

Funding: Bulgarian Academy of Sciences

Call: Program for supporting Young Scientist - 2016.

Project No: DFNP-96/04.05.16

Beneficiary Organization: IICT-BAS,

Project Coordinator: Assist. Prof. Dr. Nikolay Stoimenov

Mentor: Prof. Dr. Dimitar Karastoyanov

Abstract: An example of an investigation/study about the movement and interaction of bodies with different shapes can be considered in ball mills. Changes in the shape and size of the grinding bodies and the material for grinding can be observed in the ball mills. The bodies and the grinding material affect also the internal modules of the ball mill.

In dissertation is analyzed the types of mills, their inner lining, and the workflow. The regimes of ball mills, charging and discharging, characteristics of the grinding media are examined.

Experimentally equipment is examined, which can help for detailed knowledge contributes to proper operation. Attention is paid to nanoparticle sizer, thermography is examined. Attention is paid to software working on discrete element methods, and different modules which can be used for various simulations.

Simulations are implemented with software running on the method of discrete elements for movement of the grinding bodies in a laboratory ball mill. Innovative parameters of grinding modules are proposed (lifters for a ball mill) to obtain the best parameters of the ground material.